The B-29 Superfortress was powered by four Wright R-3350 Cyclone 18 twin-row radial engines, each with significant power and technological advancements.

Engine Specifications

- Type: 18-cylinder, air-cooled, twin-row radial engines

- Displacement: 3,350 cubic inches (54.9 liters)

- Power Ratings: Take-off power ratings ranging from 2,200 hp to 2,500 hp

- Weight: Each engine weighed 2,500 lb (1,270 kg)

- Bore and Stroke: Cylinder bore was 6.125 inches (155.5 mm) and connecting rod stroke was 6.30 inches (160 mm)

Development and Selection

Boeing’s engineers evaluated various high-horsepower engines available in mid-1940. They needed an engine capable of producing at least 2,000 hp, preferably 2,200 hp. They considered the Pratt & Whitney R-2800 Double Wasp (2,000 hp) and the Wright R-3350 Cyclone 18, which promised 2,100 hp and had better potential for power growth. Despite its initial unavailability, the R-3350 was selected for its superior future power prospects.

Production

- Initial Development: Wright started work on the Cyclone 18 in January 1936, with the prototype running by May 1937.

- Manufacturing: Wright built a new factory in Woodbridge, New Jersey, to complement its Cincinnati, Ohio, facility. These factories produced 13,800 engines. The Dodge division of Chrysler Corporation in Chicago, Illinois, produced an additional 18,400 engines. In total, approximately 32,200 R-3350 engines were manufactured.

- Early Issues: The engine faced early development problems, but improvements extended the time between overhauls from 100 to 400 hours by the end of World War II.

Technological Features

- Construction: Three-section forged aluminum (later cast iron) crankcase, cast-iron cylinder heads, and magnesium-alloy turbosupercharger casings.

- Carburetion: Early models used downdraft carburetion, leading to air and fuel mixture inconsistencies between the front and rear cylinder rows. Later models incorporated direct fuel injection to resolve these issues.

Turbocharging System

- Superchargers: Each engine was equipped with two B-11 exhaust-driven turbosuperchargers mounted vertically on either side of the nacelle.

- Operation: Exhaust gases passed through a collector ring and tail stack to the nozzle box of each supercharger. The gases expanded to atmospheric pressure through the turbine nozzle, driving a high-speed bucket wheel. This wheel, in turn, drove the supercharger’s impeller.

- Air Intake: A ram air inlet duct supplied air to the impeller, increasing its pressure and temperature. To prevent detonation at the carburetor, the air passed through an intercooler to reduce its temperature.

- Internal Impeller: Driven by the engine crankshaft, it further increased pressure as the fuel/air mixture entered the intake manifold, resulting in greater engine power output.

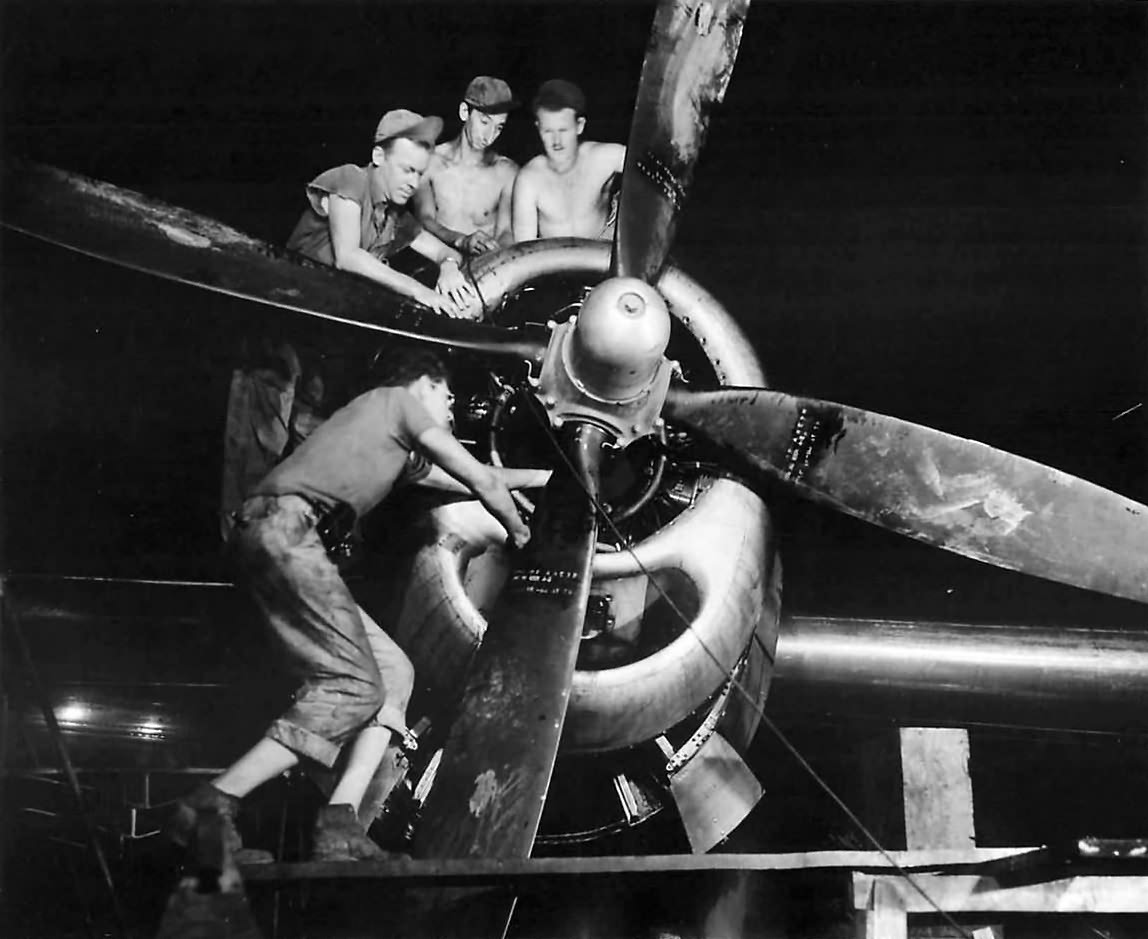

Propellers

- Type: Hamilton-Standard, four-bladed, constant-speed, full-feathering propellers.

- Control: Constant-speed control was maintained with a governor and operated electrically by four switches for individual control of each propeller, accessible to the pilot or co-pilot.

The R-3350 engines, despite their early development challenges, became a crucial powerplant for the B-29 and other legendary US military aircraft, contributing significantly to their performance and operational success.