The first turret of the Bristol Type B.I, Mk I series marked the beginning of a line of Bristol-designed hydraulically powered turrets, primarily associated with the Blenheim and Beaufort aircraft. Throughout the various sub-types, the control system remained largely unchanged, with the main difference lying in the type and quantity of guns installed. The Blenheim turret was rightfully regarded as a significant advancement in bomber defense, granting the gunner the ability to control the guns from a compact enclosed cupola with hydraulic assistance.

The turret’s hydraulic power was derived from a three-stage gear-type hydraulic pump located on the port engine, delivering 810 liters of oil per minute at a pressure of 4820 kPa. This same pump was also responsible for supplying pressure to the flaps and undercarriage, and a selector valve in the cockpit allowed the pilot to direct the oil flow either to the turret or to the main hydraulic services. To accommodate agitation and foaming, the hydraulic reservoir, which held one gallon of oil, was fixed to the bulkhead of the port engine, with space for an additional gallon. Unfortunately, early reservoir designs experienced oil loss during intense maneuvers, leading to occasional disastrous consequences. When the turret was not in use, the cupola could be partially retracted to reduce drag. This was achieved by turning a small handle on the right-hand cupola support tube, which engaged a pinion acting on a toothed rack inside the tube, lowering the dome until a spring-loaded pawl locked it in place. To extend the cupola, a release lever was operated, disengaging the pawl. The dome was then automatically raised to its full position by springs inside the support tubes.

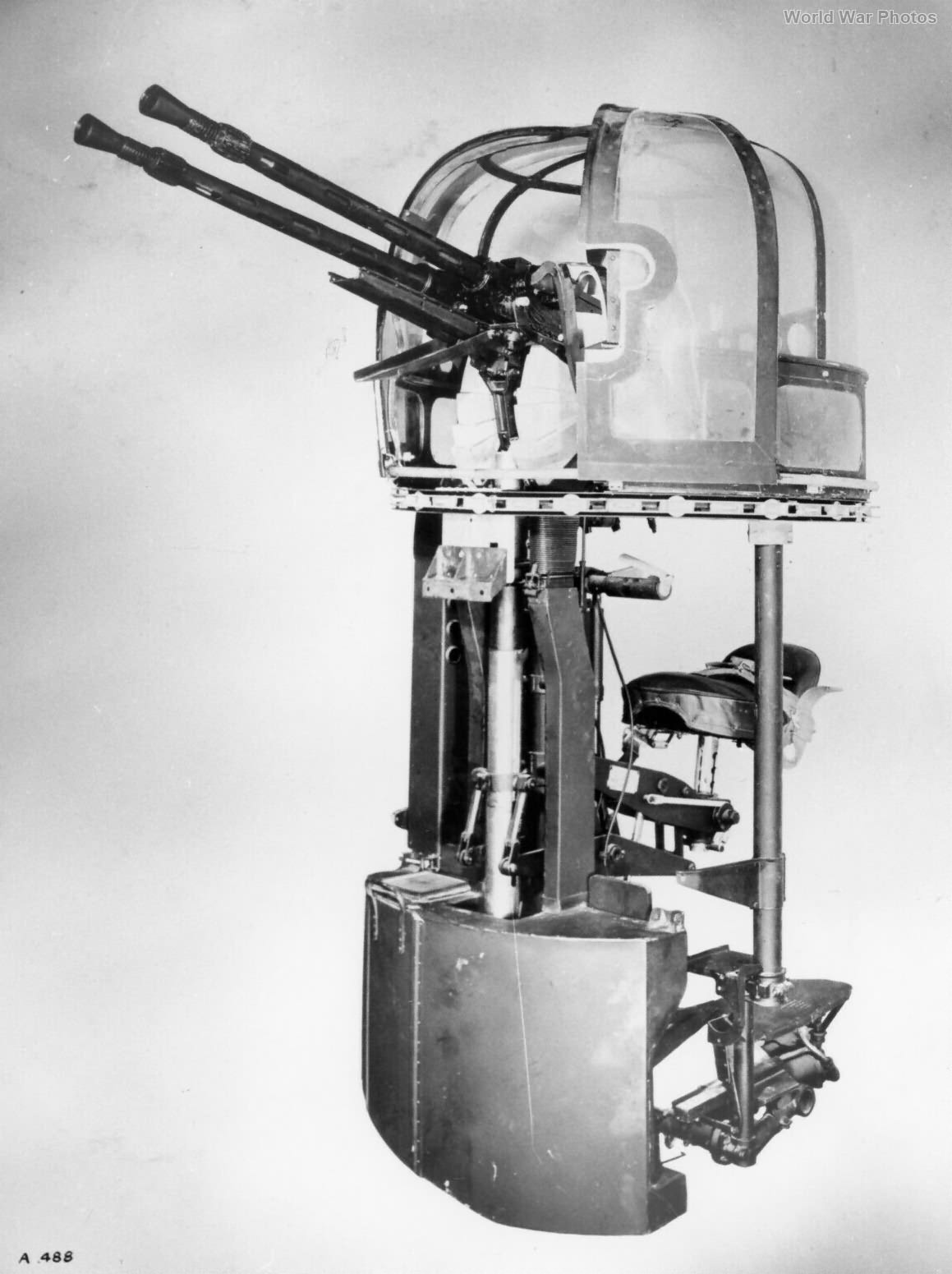

Bristol Type 1 Mk IV turret

Published at 1159 × 1551 px.

Link to full-size photo:

Bristol Type 1 Mk IV turret

Site statistics:

Photos of World War II: over 26800

aircraft: 63 models

tanks: 59 models

vehicles: 59 models

guns: 3 models

units: 2

ships: 47

WW2 battlefields - 12

weapon models: -

equipment: -