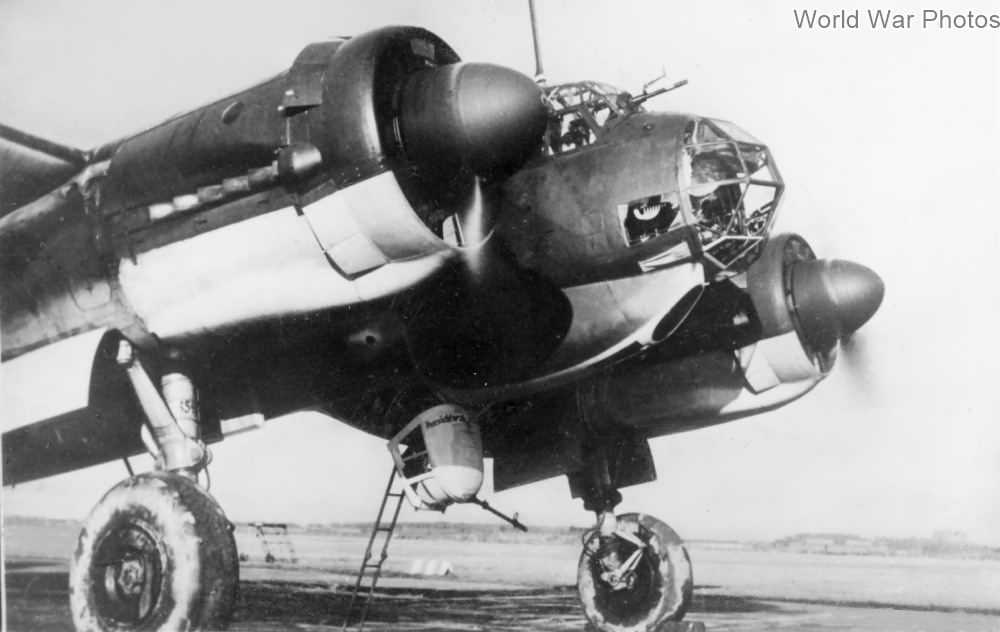

The forward-projecting engines of the Ju 88 played a significant role in the aircraft’s appearance and performance, earning it the nickname “Dreifinger” (three fingers). Key details related to the engines and associated systems:

Ju 88 Engine Specifications and Configuration

Engines: The Ju 88 A-4 variant was equipped with two Junkers Jumo 211F-1, J-1, or J-5 engines. These were 12-cylinder, liquid-cooled inline engines, each rated at 1,400 horsepower. The liquid cooling system was crucial for maintaining optimal engine temperatures, especially during extended operations at high power settings.

Propellers: These engines drove three-bladed wooden variable-pitch VS 11 propellers. The variable-pitch feature allowed the propeller blades to adjust their angle, optimizing performance across different flight conditions and improving efficiency.

Cooling System: A distinctive feature of these engines was the five-segment annular cooling ring, one of which was dedicated to oil cooling. This ring was positioned around the engine, giving the appearance of a radial engine due to its forward placement. Additionally, there was a secondary radiator located on the underside of the engine nacelles, with an asymmetrical elongated covering. This setup enhanced the cooling efficiency, crucial for maintaining engine performance and preventing overheating.

Fuel System

Main Fuel Tanks: The Ju 88 had self-sealing fuel tanks integrated into the wings. These were strategically placed between the fuselage and the engines, with each inboard tank holding 415 liters and each outboard tank holding 425 liters. The self-sealing nature of these tanks was a protective measure against damage from enemy fire, minimizing the risk of fuel leaks and fires.

Drop Tanks: For extended range, the aircraft could carry additional drop tanks of 300 or 900 liters. These were mounted on standard ETC 500 racks positioned ventrally (on the underside of the aircraft). Drop tanks were typically used to increase the operational range of the aircraft for longer missions.

Fuel Pump System: In the event of a failure in the main fuel system, the crew could manually operate a hand fuel pump located in the cockpit, providing a backup means of delivering fuel to the engines.

Oil System

Oil Tanks: The oil system was supported by wing-mounted tanks with a capacity of 272 liters and an additional 106-liter tank. These tanks supplied the necessary lubrication to the engines, crucial for maintaining their operation during prolonged flights.

Oil Pumps: The engines were equipped with oil pumps to circulate the oil, but they could also be manually operated if needed. This manual option was a critical backup feature, ensuring that the engines could continue to receive lubrication even in the event of an automated system failure.

Electrical System

- Bosch Generators: The engines also powered two Bosch generators capable of producing 2,000 watts each. These generators were part of the aircraft’s screened electrical system, providing a voltage of 24V. The electrical system powered various onboard systems, including avionics, lighting, and other essential electrical equipment.